Mitigate coastal erosion and storm damage with J.G. Michalski shoreline protection and restoration engineering and construction services. We offer risk evaluation of your shoreline property. If you have a constructive plan to restore the shoreline from previous damage, we are prepared to step in and meet your project needs. We tailor our coastal engineering techniques to your site’s specific characteristics and environmental composition to ensure long-term coastal protection and sustainability.

Let our engineers guide your shoreline protection project through every step to a successful completion. We will be there wherever you need us to step in; from the survey to the design, permitting and construction stages.

At J.G. Michalski, we understand how important your waterfront property is to you. It’s more than just property, it’s an investment. Many times, situations and environments present challenges that require us to think outside the box. Our services are available year round, and we pride ourselves on getting the job done right & on-time.

Mitigate coastal erosion and storm damage with J.G. Michalski shoreline protection and restoration engineering and construction services. We offer risk evaluation of your shoreline property. If you have a constructive plan to restore the shoreline from previous damage, we are prepared to step in and meet your project needs. We tailor our coastal engineering techniques to your site’s specific characteristics and environmental composition to ensure long-term coastal protection and sustainability.

Let our engineers guide your shoreline protection project through every step to a successful completion. We will be there wherever you need us to step in; from the survey to the design, permitting and construction stages.

Steel sheet piles are long structural sections with a vertical interlocking system that creates a continuous wall. The walls are most often used to retain either soil or water.

Steel seawalls have a very long service life and they are the most economical choice when considering a seawall to protect your shoreline. Plain steel seawalls are also the best option where heavy ice pressure is present, and a heavy duty wall is required.

Life expectancy of a steel wall using 8 gauge material is 25+ years.

Our Skip Pole wall consists of dimensional lumber spaced apart the width of the material for the entire length of the wall. In areas with heavy wave action and currents, a porous seawall of the skip-pole variety backed by rip-rap is frequently used to help minimize scouring of the toe of the wall by waves and currents.

The use of pressure treated white and red oak for construction of this type of wall provides a durable and natural finished look that will provide up to 25+ years of service.

Rock shorelines are installed at a 2-to-1 slope backed with Geotextile fabric using 4 to 5 feet diameter native limestone boulders. Boulders/Rip Rap are great alternatives to “seawalls”. They can be used as a method of repair and when installed correctly can be a very effective form of erosion control. We love to think outside the box, and the riprap boulder design can be incorporated with trees and other native landscape. Our rock, boulder & rip rap revetment shorelines have a natural environmental aesthetic to any custom landscape.

Made from pressure treated lumber, wood seawalls are sometimes less inexpensive than alternatives such as vinyl and composites. J.G. Michalski seawalls are effective at preventing erosion because they break the force of the waves. The wood that is used for these walls is treated so that it will not rot. Wood seawalls can be expensive, but they will last for many years.

Concrete seawalls are made using reinforcing steel (rebar) and are very strong. When constructed well and properly maintained, they may last over 30 years. To ensure a long life, however, it’s essential that any cracks are patched and that care is taken to stop the joints from separating. If water gets into the wall, it can cause the steel to rust and weaken the structure considerably.

Anchor your seawall with engineered earth anchors to create an impenetrable barrier and protect your land.

Earth anchors are steel or wood anchors which can be driven into the soil, connected to a threaded tie-back, and mounted on a steel plate bolted to the seawall. These earth anchors can strengthen your seawall and help it last even longer.

Benefits of earth anchors:

The expert designers on staff at JG Michalski LLC will help you develop a visual concept of your project before building begins. Whether you need a seawall design, or deck design, JG will offer ideas for layout, dimensions, and materials before turning the project over to our builders, who will see the project through to fruition making sure the appropriate materials are used and that construction meets all required codes to pass inspections and gain permits.

A well-constructed deck can turn underutilized land into a pleasant outdoor living space and even increase the square footage of your house by adding a working platform over water. From freestanding decks to patio decks secured directly to a seawall, JG will work with you from the design phase onward to build the deck that improves your lifestyle.

It is the mission of JG Michalski LLC to provide environmentally-friendly marine construction services to all of our clients. We strongly advocate the use of installation techniques that provide minimal or no impact to the environment and complete every job with respect to the surrounding landscape and marine wildlife.

Adherence to this mission enables us to protect the shoreline, shield the environment and consistently abide by federal, state and local environmental protection guidelines.

The expert designers on staff at JG Michalski LLC will help you develop a visual concept of your project before building begins. Whether you need a seawall design, or deck design, JG will offer ideas for layout, dimensions, and materials before turning the project over to our builders, who will see the project through to fruition making sure the appropriate materials are used and that construction meets all required codes to pass inspections and gain permits.

A well-constructed deck can turn underutilized land into a pleasant outdoor living space and even increase the square footage of your house by adding a working platform over water. From freestanding decks to patio decks secured directly to a seawall, JG will work with you from the design phase onward to build the deck that improves your lifestyle.

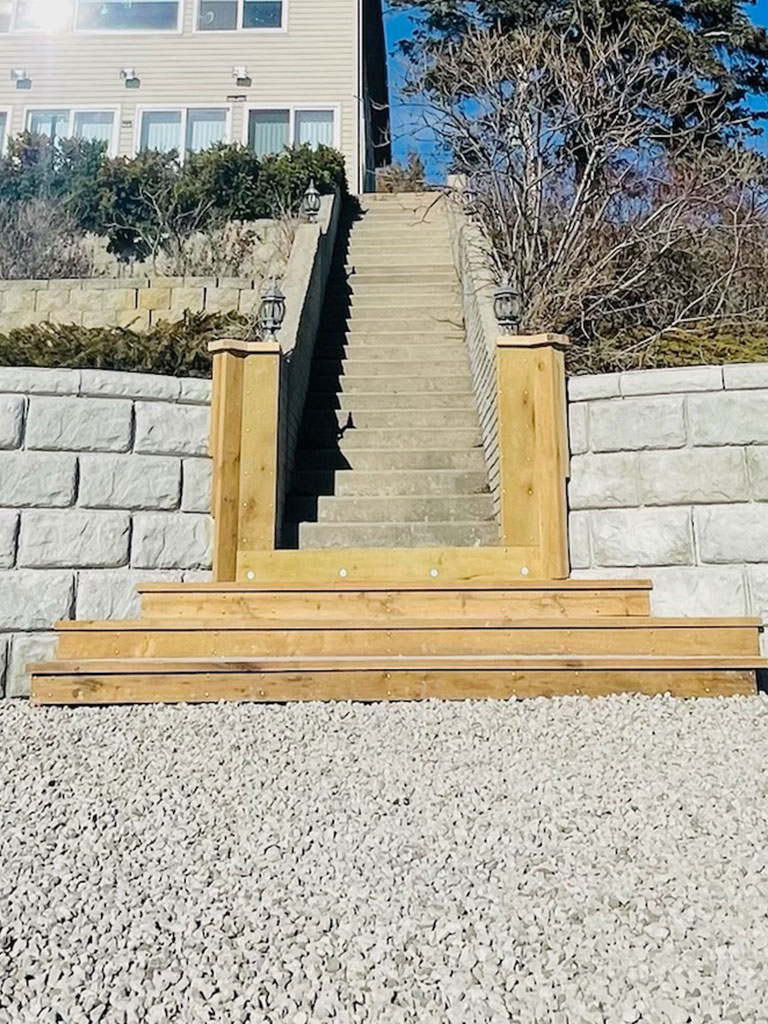

To compliment your new deck or rock revetment, JG Michalski LLC can design and install a custom access well(s) that best suit your needs. An access well is a permanently installed staircase that will allow you access to the water. Access wells will allow you to move people, and watercraft to the shoreline with ease.

All access wells can be custom made to allow for your personal needs.

Retaining walls are relatively rigid walls used for supporting soil laterally so that it can be retained at different levels on the two sides. Retaining walls are structures designed to restrain soil to a slope that it would not naturally keep to. Common retaining wall types include gravity walls, cantilevered walls, crib walls, gabion walls, and sheet pile walls, etc. We offer a variety of different retaining wall options to meet your needs, including seawalls and marine construction. Seawalls are retaining walls built along coasts and inland bodies of water to protect against erosion from waves and currents. Marine construction is the process of constructing retaining walls in marine environments. Our team of experienced professionals has the expertise and equipment necessary to build retaining walls in even the most challenging marine environments. Contact us today to learn more about our retaining wall options and to get started on your project.

Steel sheet piling is one form of retaining wall construction. Sheet piles resist soil and water pressures by functioning as a beam spanning vertically between points of support. Steel sheet piling is a type of retaining wall construction that is commonly used to fortify waterfronts and other areas prone to soil and water pressure. Sheet piles are typically steel beams that are arranged horizontally across the ground in a series of interlocking upright posts. This design helps steel sheet piling to resist both upward and lateral pressure from soil, water, and other outside forces, effectively creating an impenetrable wall that can prevent erosion, flooding, or other damage to surrounding areas. Because steel sheet piling is flexible and versatile, it can be used in many different applications, from building seawalls along coasts to protecting agricultural fields from runoff during heavy rains. Whether it is used as part of new construction or retrofitted into existing steel structures, steel sheet piling is a highly effective way to protect vital infrastructure against the effects of nature’s forces.

Railway sleepers slotted into RSJs (rigid steel joists) or steel H or I beams have traditionally been used on farms, builders yards, and commercial settings for decades, to create strong retaining walls, silo bays, aggregate bays, boundary walls etc… More recently this type of railway sleeper wall has also been used in domestic gardens, where the height or strength that is required is above the normal dimensions or specifications of building retaining walls with railway sleepers. Alternatively they are now used in situations where the garden designer wants a more industrial look to the project.

Gabion walls – function, application, advantage

The word “gabion” comes from an old Italian word, gabion, which means “big cage.” Around 7000 years ago, early gabion type structures protected the bank of river Nile. In the middle ages, gabions were used as military forts. In earlier history, civil engineers have extensively used gabions for stabilization of banks, coasts, highways and erosion control of slopes. From the banks of river Nile, where they were created up through today, gabion walls are a benefit for the landscape. It is used for thousands of years as a gravity type retaining structure and makes an attractive, efficient and cheap wall system.

Gabion walls are executed mainly for the purpose of soil stabilization behind the wall, but it can also be executed as a cover wall. The wall is made from gabion baskets that are stacked in one or more rows, depending on the height of the wall. Baskets have a cage shape and are closed on all sides. They are made from a galvanized hexagonal meshes and broken rock that are placed in the baskets. Retaining structures are formed by stacking gabion baskets in a proper schedule and present an alternative solution for concrete structures in the area of soil stabilization.

The versatility of the Redi-Rock system allows retaining wall engineers and landscape architects to create custom retaining wall solutions for a wide range of projects—including municipal and residential projects; water application projects including shoreline protection, storm channels, and retention pond; bridge abutments, wing walls, and culverts; railways projects; DOT work and road construction projects. With Redi-Rock, you can design tall gravity walls and even taller reinforced walls with the Positive Connection (PC) System.

With 5.75 sq. ft. of face per block, Redi-Rock retaining walls and Freestanding walls go up fast—plus, the design of Redi-Rock blocks allows for curved walls, 90 degree corners and much more to make a custom wall simple to install.

With Redi-Rock, it’s simple to vary batters, create inside and outside curves, integrate freestanding walls, steps and much more. Additionally, extensive retaining wall design resources are available, including Redi-Rock Wall Analysis Software for gravity retaining walls, construction details, designs charts of over 700 of the most common conditions and much more. Professional Engineers on staff at Redi-Rock’s engineering department are available to answer your questions and help you find a Redi-Rock solution for your project.

Redi-Rock retaining wall blocks are made from architectural-grade precast concrete which creates durable retaining walls that will stand the test of time. Plus, coordinating freestanding walls with columns, steps, caps, and pavers help create a cohesive look.

Redi-Rock walls are available in three textures—Ledgestone, Cobblestone, and Limestone—to match your project’s aesthetic requirements.

Redi-Rock installs like a one-ton Lego, and who doesn’t love playing with Legos? Each massive, one-ton block has a knob and groove design that makes retaining walls fast and easy to install.

All that’s required is an excavator (size dependent on block weight) and a 1-2 person crew. With 5.75 sq. ft. of face per block, retaining and freestanding walls go up fast—plus, the design of the blocks allows for curved walls, 90 degree corners and much more to make a custom wall simple to install. Tall gravity walls are possible with Redi-Rock–meaning you won’t have to mess with installing geogrid in many applications. For even taller walls, the incredibly efficient PC System for reinforced walls makes your job easier.

With fork slots for easy loading and unloading during retaining wall construction, you’ll be glad you chose Redi-Rock for your project!

Need help with a project or are you interested in our services? Contact us so we can talk today.

At J.G. Michalski, we understand how important your property is to you. It’s more than just property, it’s an investment. Many times, situations and environments present challenges that require us to think outside the box. Our services are available year round, and we pride ourselves on getting the job done right & on-time.